1. Laser etching and engraving is 25-50% cheap!

2. Excellent quality guaranteed – modern equipment is used.

3. Help in creating a drawing using laser etching.

4. We are waiting for you to take your order and give you a ready-made one any day of the week!

5. We work near you in the Tries Cities area – Coquitlam, Port Coquitlam, Port Mood, Burke Mountain, Westwood Plato and Oxford Heights.

Laser engraving near me – what is it

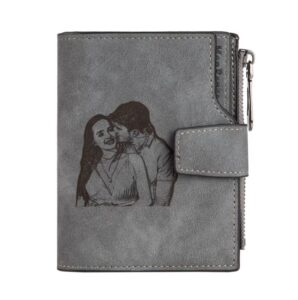

When searching for laser etching near me, you’ve probably already decided what you want to get. The technology is used to apply images, inscriptions and symbols to coins, badges and medals. In order to make the contours of numbers, letters, inscription elements and images stand out when applying a logo, the method of contour engraving is used. This method is relevant when working with medals and coins. If it is necessary to apply a more precise image, use the raster engraving method. It is mainly used for applying almost photographic images to badges. The operating principle of this method is not complicated – the laser applies thousands of points of different planes to the surface, which form an image.

Laser technology allows you to make unique and original medals or coins, as well as other products. When searching for custom etching near me, you should decide what the order executor will have to do. The products can serve as an interesting gift and become a good souvenir. Laser engraving technology is widely used to create corporate products – special insignia and regular badges, all of which are souvenirs. Options for applying photographs, logos, and decorative drawings based on customer sketches are possible. Laser engraving is suitable for processing a variety of alloys, precious metals, plastics, wood and leather. The processing process occurs quite quickly – using a laser beam is the most efficient way.

Laser engraving Vancouver BC – advantages

- Mugs and flash drives;

- Pens and diaries;

- Lighters and keychains;

- Umbrellas and clocks.

Laser etching metal is also in demand on other materials. Modern technologies make it possible to apply images of any complexity to objects of various shapes. Now it has become possible to apply small inscriptions, complex designs and logos to objects.

Laser engraving equipment is one of the most technologically advanced and progressive ways of applying images to solid objects. It has a number of advantages compared to other methods. These include the following:

- No heating during the engraving process;

- No need to secure the item during processing;

- It is impossible to damage the object that is being painted with a picture or inscription.

With stationary or portable laser etching, it becomes possible to apply texts or images to objects of any configuration. Full automation of the process ensures low prices for bulk or serial orders. In addition, the engraving is precise and durable.

The advantages of laser marking and engraving make it possible to use this technology in a wide variety of industries, including both for the production of high-precision products and for aesthetic purposes. In the modern world, it is possible to engrave not only souvenirs, but even various postcards. The possibilities of advertising logos are becoming limitless. Now they are applied to almost any surface and are of high quality.

However, many often wonder whether it is worth engraving on license plates, key rings and other small-sized items, when there are ways to engrave an image much cheaper and easier. Is it worth using laser aluminum engraving, for example? Engraved images are more durable. They will last much longer than stenciled images. Laser engraving will not be erased throughout its service life, but will remain as neat as in the first days.

The production of advertising and award products for corporate clients, as a rule, is much cheaper. This is due to the order volume. However, large companies pay no less attention to individual clients. They strive to answer all their questions, complete the order so that the client is satisfied and turns to them next time. Each person receives an individual approach.

Engraving on metal – features

You can apply an image to metal using a laser. The laser method is many times superior to manual application of an image, because this process is completely automated. As a result, work completion time is significantly reduced, accuracy is increased, and defects are minimized. Laser engraving on metal involves the use of light radiation. It is possible to automatically adjust its power, the diameter of the laser spot, and the depth of exposure. As a result of laser etching stainless steel, you can get a pattern of different tones, change the relief, and structure the surface of the product. The technology itself involves removing a layer of material to form an image on its surface. At the same time, you can work with different types of metals. Thus, laser etching aluminum is in great demand.

Engraving stainless steel and other types of metal can be of several types:

- With changes in surface topography. The laser acts on the workpiece, heating it pointwise to a temperature at which the metal evaporates. By changing the beam power, you can adjust the depth of the part of the workpiece being removed, as a result of which the relief changes. This is how the image or inscription is formed.

- When laser engraving aluminum or on the surface of another metal, the image is outlined along the contour. Hence the name – contour. It is used when applying small inscriptions on small objects: coins, awards, etc. The design will stand out on the surface.

- Color contrast image. The metal surface is heated pointwise to the melting point. During the transition from solid to liquid, the structure of the material changes. As a result, after crystallization, the color of the surface changes. The image appears as a contrast between unformed points and those that were affected by the laser beam. Implementation may not be possible on all materials.

- When working with thin products, it is mainly performed using special pastes or sprays that are applied to the surface of the workpiece. These compounds catalytically prevent deep penetration of heat, so that only a thin layer of metal burns out. After completing the work, wash off the paste or remaining spray.

- Laser engraving on metal with electrolysis. It is used primarily when working on spherical and cylindrical surfaces. Varnish or paraffin is used. Cheaper in price than using paste. It involves the creation of an electrolytic bath, which increases the complexity and duration of the engraving process. Initially, the surface of the workpiece is coated with varnish or paraffin. Next, an image is applied to it using a laser machine. Afterwards, the workpiece is placed in a bath with a water-salt solution so that the varnish layer remains above the surface. Electrodes are placed in the container, to which a direct current source is connected. “Plus” is applied to the workpiece, and “minus” is applied to the electrodes. This produces a clear, high-contrast image with a depth of only 0.1 mm. After completion of the work, the varnish is removed.

Each of these types of laser etching aluminum or other metal using a laser beam has its own characteristics and areas of application, which must be taken into account by craftsmen when performing work.

Wood etching – features

Natural wood products are becoming increasingly popular. It is used to produce household items, souvenirs, promotional materials and much more. One of the popular processing technologies is laser cutting of wood and engraving.

The preparation and processing process does not take much time, which is a definite advantage. But to obtain high-quality products, several factors must be taken into account. This is something to keep in mind when you are looking for wood etching near me.

Wood engraving involves local heating of sections of a wooden surface using a laser machine. As a result, the desired pattern remains on it. It is possible to apply any patterns, inscriptions and even photographs. The flexibility of wood for processing depends on its type:

- Birch, maple and beech provide the best image quality with high contrast;

- Aspen and maple require the use of oil impregnations to obtain a clear image;

- Pine is the worst wood to process, even when using special impregnations.

It is important to take these nuances into account when choosing materials and preparing the technical production process.

The production process of armored wood products has the following algorithm:

- Image development in a special program;

- Selecting the type of wood, sanding and pre-impregnation;

- Laser engraving;

- Coating with a protective composition.

The process requires the correct choice of wood etching mode, taking into account the type of wood. Using engraving technology, you can create original things without much time.

Glass laser engraving – features

Laser glass etching allows you to apply high-quality designs of any complexity that will not be erased over time, with high speed and accuracy. As a result, you get an almost finished product that does not require any special additional processing.

What products are produced using laser engraving? Using engraving glass, various designs, logos, patterns, photographs and text are applied to finished products. Often these images are personalized to order. Typically, laser engraving is applied to glasses, glasses, bottles, and vials. In addition, by applying a design to the glass and placing it on a backlit stand, you can get a spectacular lamp. Cast glass is best suited for laser engraving, but other types of glass, such as crystal, can also be easily engraved with a laser if the settings are selected correctly.

- awards, prizes, cups;

- dishes, wine glasses, glasses, glasses;

- bottles of wine, whiskey and other alcohol;

- car mirrors.

Engraving fragile glass products requires precise and professional equipment. Laser imaging technology works very carefully with fragile materials without damage. Engraving is carried out with clear detail of the inscription and does not deform the product. Laser drawing is performed at high speed, so engraving orders are completed quickly. Working with one glass will take no more than half an hour. Engraving of glasses is done using a rotary device.

There is also engraving glass in 3D. Volumetric 3D engraving is the application of three-dimensional engraving inside glass crystals. The image inside the crystal consists of such points. The drawing can be anything, geometric shapes, words, images of animals and people. This engraving method is used in the manufacture of souvenirs, gifts, design decorative elements, logos and symbols. When applying 3D engraving, the laser creates a microexplosion ranging in size from tens to hundreds of microns, which appear in the form of silvery dots, while the product is not damaged or deformed. Microfracture occurs inside the glass.

Laser etching – other materials

Also popular is laser engraving acrylic. Again, these can be a variety of products. For example, this could be some original items used to decorate the interior. Laser etch acrylic is also ordered to solve commercial problems. In particular, these can be signs that are installed on the desks of company employees or hung on office doors. Laser engrave on acrylic technology, as with other materials, requires a professional approach. Only in this case can you obtain high-quality products.

Laser etch plexiglass is in demand. Various products are made from this material today. It is used in various areas of our lives, including the business area. High-quality plexiglass laser etching allows you to add originality to ordinary objects. Of course, you need to know how to properly work with such material. Because, despite the strength of plexiglass, it can be damaged when working with a laser engraver.

Equipment used for applying pictures – laser engravers

Companies that provide related services use laser engraver in Canada. This is special equipment, it processes the material step by step, creating a convex or in-depth pattern on a flat surface. Using this principle, you can create very complex ornaments, patterns, and inscriptions using laser etching Canada. Depending on the intensity of exposure, high shade distinction is achieved, and the resulting image is of photographic quality. A big advantage of laser etched is also the high accuracy of reproduction of a given image and repeatability in mass production. Laser engravers are widely used for highly artistic engraving. In addition to special quality, the technology allows you to perform operations that are inaccessible to traditional machining. This is engraving on thin and fragile surfaces, leather, textiles, rubber, miniatures. Of course, today there are many such devices. If you are looking for a laser engraver near me, or rather a company that has such equipment, then before ordering we recommend that you clarify which machine is used. Because only a modern device is capable of producing high-quality inscriptions and drawings.

Custom etching near me – price

How much does it cost to order laser etching and engraving? The cost of engraving depends on:

- number of engraved items;

- number of engraved sides of the product;

- engraving content (text only or text with pictures);

- engraving area and product size;

- complexity of the work performed (complex technical specifications increasing the average time to complete the work, non-standard shape of the product, etc.)

If you decide to order the appropriate service, then you are doing the right thing. Cost, of course, plays an important role, but quality, if the work is performed by a reliable company, will clearly prevail in this case.

Laser cutting – difference

The laser cut process is different from the laser engraved process. In both cases, laser equipment is used. But if, for example, we are talking about a wood laser cutter, then it is not assumed that pictures or inscriptions will be applied to the surface of the wood. Laser cutting services are available when you need to cut material into parts. The laser cutting method is characterized by high accuracy and considerable speed. But with laser cutter service we are not talking about engraving. Because different equipment is used, namely a laser cutter. If you are looking for laser cutting near me, then when contacting a company that works with the appropriate technology, you need to clarify what kind of service you need.